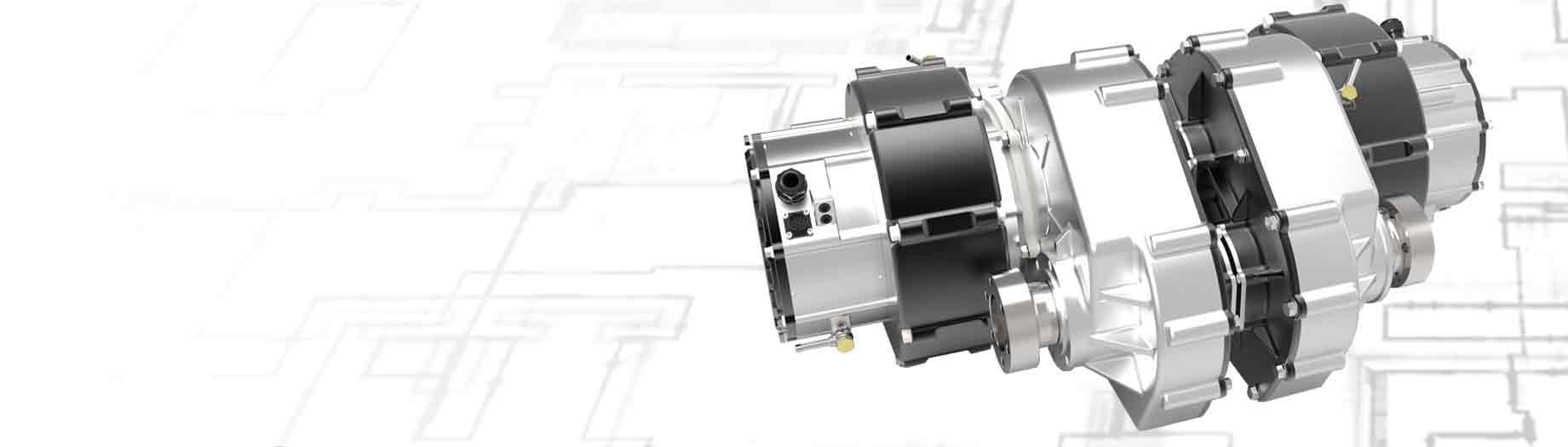

Series hybrid mechatronic transmissions for a vehicles based on Switched Reluctance Motors/Generators (SRM/SRG)

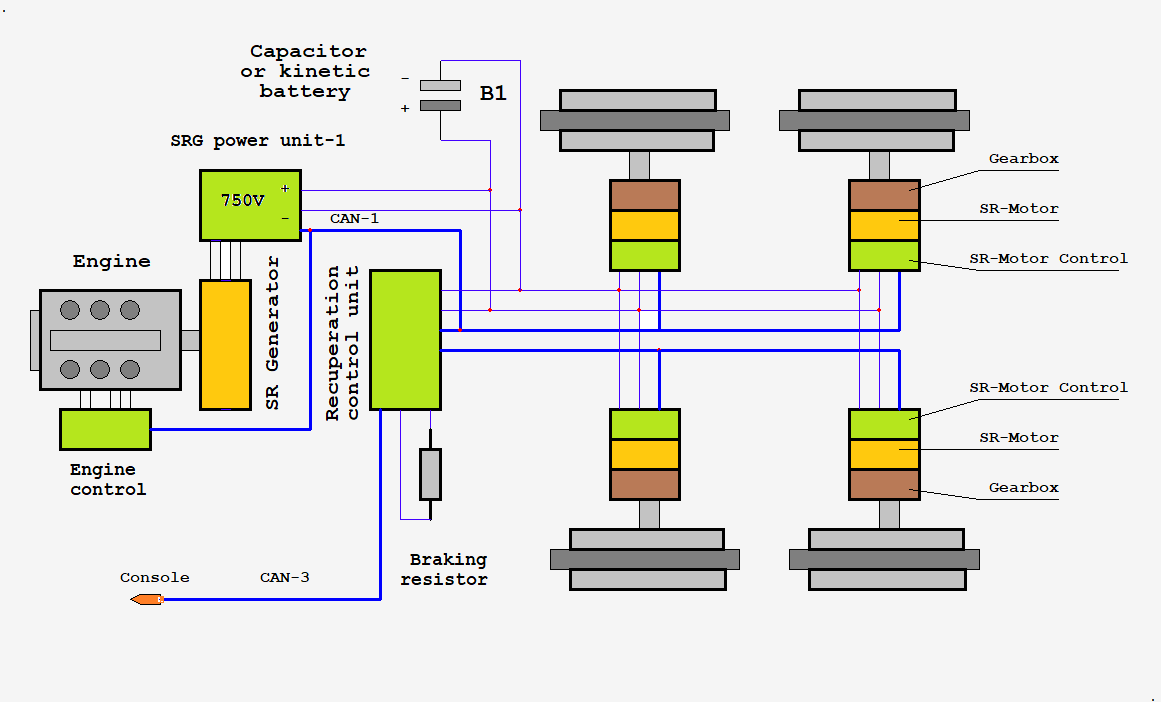

A series hybrid transmission is a powertrain in which there is no mechanical coupling between the internal combustion engine (ICE) and the drive wheels of the vehicle. ICE functions as a prime mover for a generator which is electrically coupled with a traction drive (electric motor), while the motor in turn is mechanically coupled to the wheels. The quantity of electric traction motors is determined by the quantity of the driving wheels or axles of the vehicle; the system may have anywhere from one or two to four or more traction drives. Additionally, the system may include an energy storage device (a battery, a supercapacitor or an electromechanical device known as flywheel storage) which is connected to the DC bus. The battery stores recuperated energy and, working in parallel with the generator, allows for short-term increase of the system power (e.g. during acceleration of the vehicle).

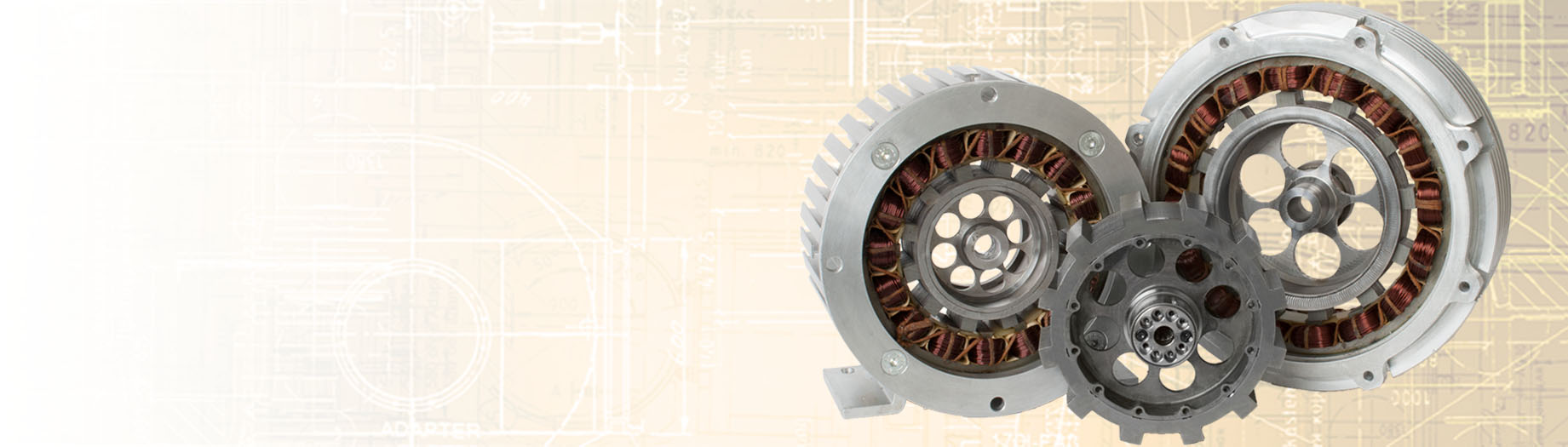

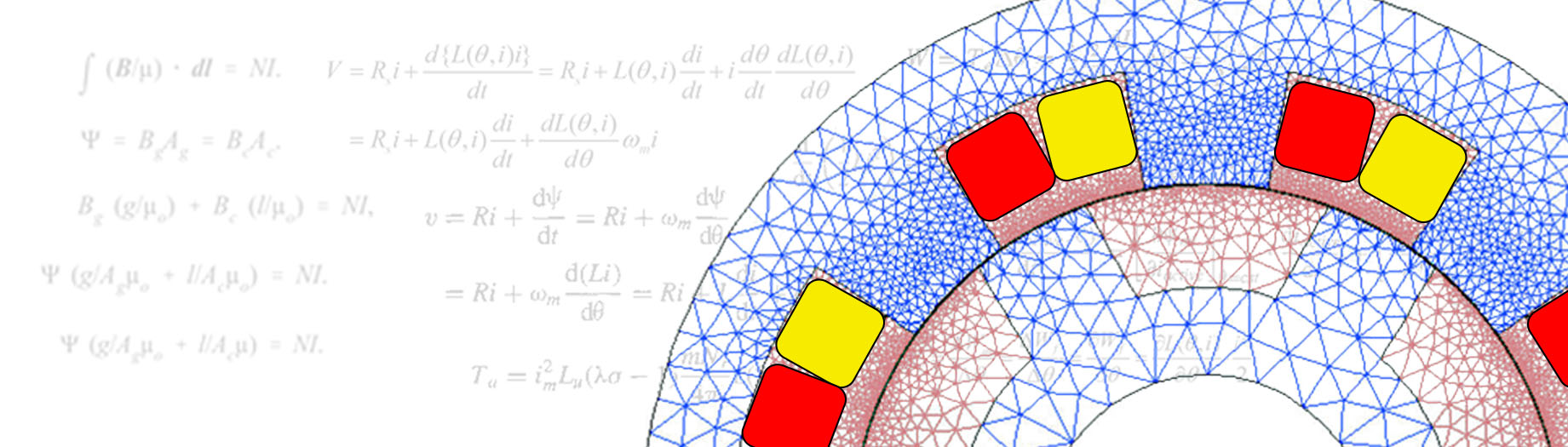

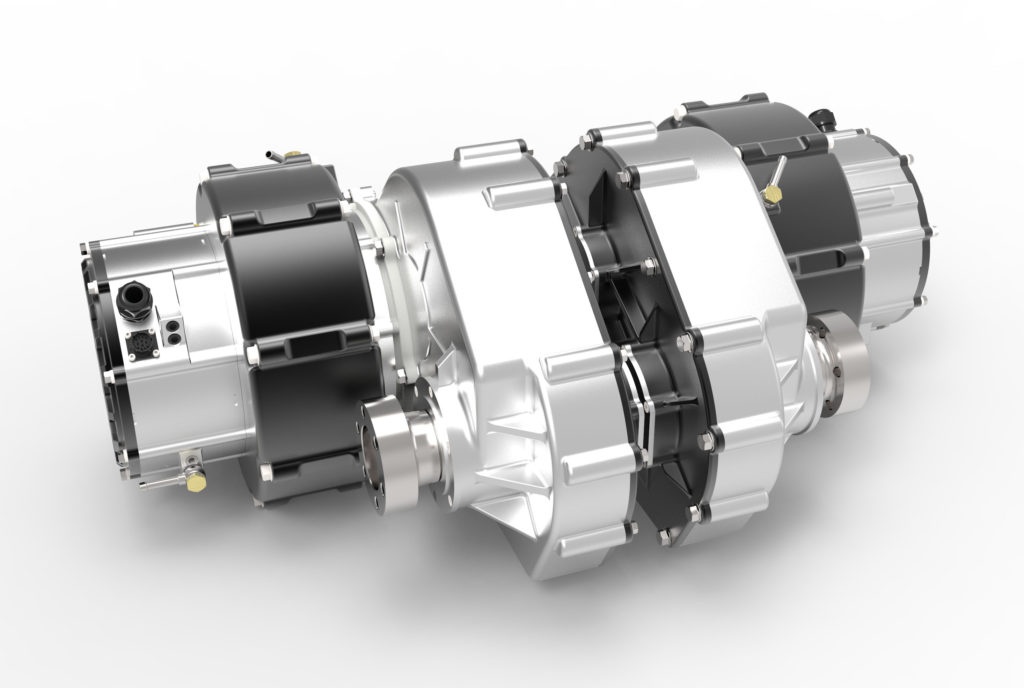

The main requirements for electric motors used in series hybrid transmissions are high power density characteristics and high efficiency in a wide range of rotation speeds, often in excess of 20:1 — precisely the area where switched reluctance machines are the leaders.

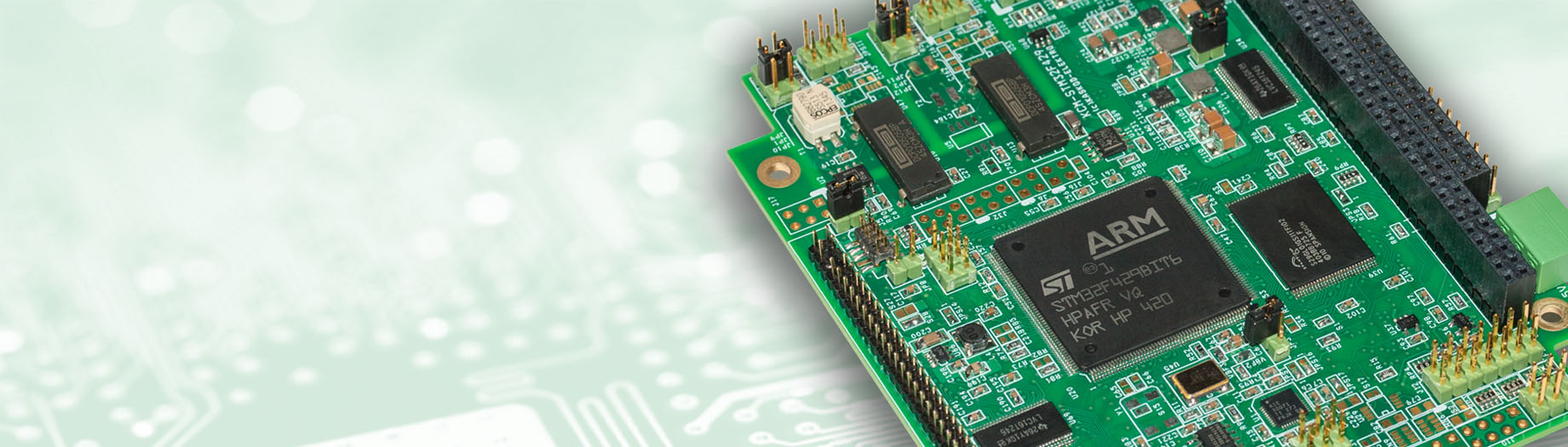

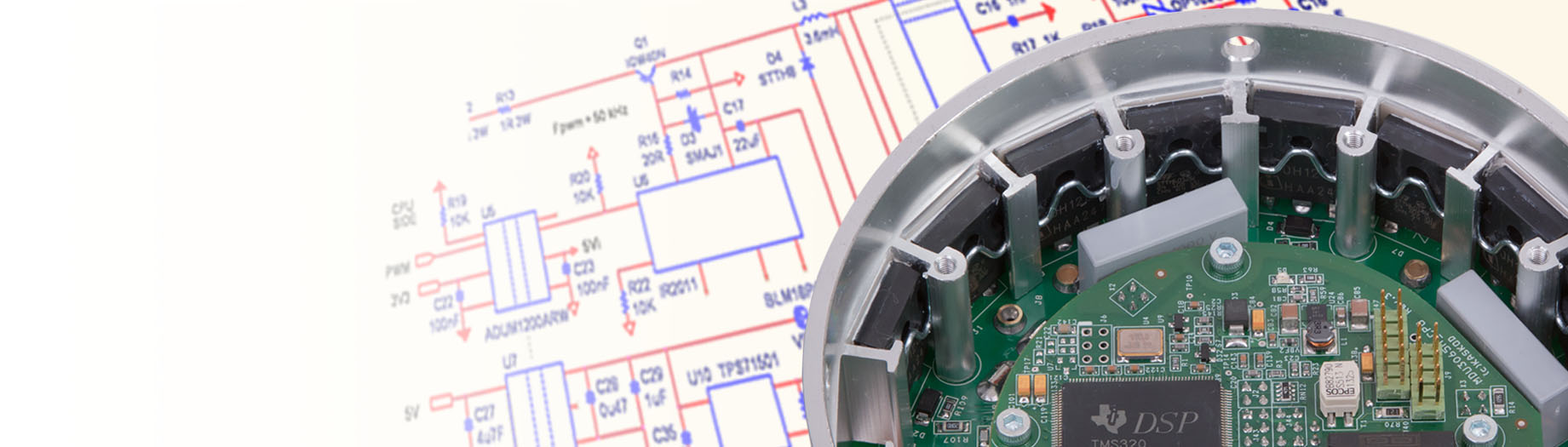

Series hybrid electric transmission has been used in rail transport for many years. In the past, this was due more to reliability issues with high-power transmissions than to fuel efficiency. However, increasing pressure from rising fuel prices and higher emissions standards is now shifting these technologies to less powerful vehicles. The introduction of this technology to the market was also facilitated by the emergence of new high-efficiency IGBT- and MOSFET-based electric motor control systems, which entered mass production in the late 1990s and early 2000s. More recently, a new generation of silicon carbide and gallium nitride power MOSFETs has emerged, significantly increasing efficiency of brushless motors and generators, accelerating the adoption of hybrid systems in the automotive industry. In this regard, the use of transmissions with manual and automatic gearboxes, which have low efficiency, reliability and poor environmental friendliness, has become an anachronism.

Main advantages of the series hybrid powertrain

compared to the mechanical transmission

- Switching-free, single-gear smooth speed adjustment of the vehicle in the full speed range, with fast reverse;

- Fully electronic control of the transmission operation;

- Low fuel consumption due to high-efficiency switched reluctance motors and generator (system efficiency of 96-98%) and optimal operating mode of the ICE which is always functioning in its high-efficiency zone;

- When energy storage is included, energy recuperation is possible.

- Low emissions (ICE always functions in high-efficiency mode);

- High system reliability (simplified mechanics, smaller quantity of rotating parts), absence of mechanical coupling between ICE and drive wheels/sprockets, electronic protection of ICE from overload, increased MTBF and lifetime of the ICE;

- Since traction characteristics of transmission are determined by traction performance of the electric motors, it becomes possible to utilize modern high-RPM ICE, micro turbines and other engine types, as well as various electric energy sources, such as fuel cells and various battery types.

- Changing the prime mover type doesn’t require major modifications of the powertrain

- High overload capability of transmission is determined by overload capabilities of the electric motors and electric energy storage;

- Better dynamic performance (short reaction time of the electric motors to the controlling actions);

- Lower level of noise and vibration, since ICE operates with minimal overload and in optimal zone;

- Regenerative braking increases lifetime of braking pads and disks, or even allows to eliminate them altogether;

- Lower maintenance costs (fewer mechanical parts that are subject to wear and less lubrication required);

- A possibility of utilizing the electrical generator of the parked vehicle to supply AC electricity to external load, if a 1- or 3-phase inverter is added;

- Good controllability of the electronic differential due to switching the power to different wheels/sprockets during vehicle turns, accomplished via electronic processing of the telemetry from the power steering or steering servo-system;

- Lower production costs due to fewer mechanical parts in the system;

- Better repairability.

A series electromechanical powertrain may include an electronic differential which provides independent control of the torque on each driving wheel/sprocket on the axle and offers a number of advantages compared to a mechanical differential:

- Absence of complicated mechanical differential;

- No bevel gears, no mechanical tuning required;

- Full control over traction performance of the vehicle;

- Improved stability of the vehicle, especially during turning and in slippery driving conditions (Electronic Stability Control, or ESC);

- Absence of energy loss during braking, ensured by Electronic Stability Program (ESP®), which applies brakes to the right or left wheel via hydraulic braking system;

- In a tracked vehicle, electric motors can rotate drive sprockets in the opposing directions allowing for the minimal turning radius (on-the-spot turn);

- Improved all-terrain driving performance;

- Improved system safety;

- Characteristics of the electronic differential can be changed in software based on the operator’s preferences and driving conditions;

- Independent control of regenerative braking of each wheel (Anti-lock Braking System or ABS);

- Wheel torque is no longer limited to the torque of the wheel with the lowest traction;

- Traction of drive wheels/sprockets is constantly measured;

- Low reaction time of the system (reacts 10 times faster than a mechanical differential);

- Lower manufacturing costs;

- Higher reliability;

- Better repairability.

Electronic differential system provides independent torque control of each wheel upon receiving and processing the telemetry from the sensors of the steering system and accelerator pedal.

Implementing the electronic differential does require more electric motors but each of them has less size and weight and requires less power (60% of power with two drive wheels and proportionately less power with further increase of the quantity of drive wheels).

Series hybrid transmission for tracked vehicles

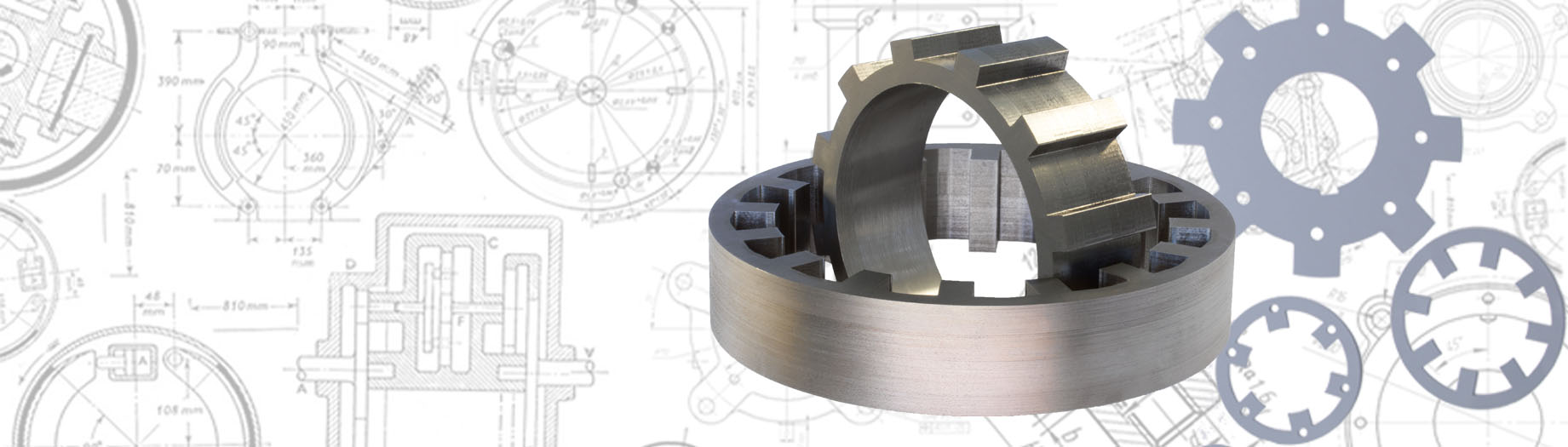

The main advantage of tracked vehicles is their excellent mobility, especially on rough terrain. A high-performance and reliable transmission is an important part of the system that determines the efficiency of the vehicle, and is responsible for all drive, steering and braking functions. A serial hybrid electric transmission meets these requirements in the best possible way. It also provides flexibility in the internal layout, allowing for the optimization of the placement of the main transmission units. The shafts and other mechanical parts of the powertrain and steering are replaced by cables, which allows for a variety of layout options and improves maintainability. The use of a complex transverse drive transmission is eliminated; instead, the vehicle is driven by valve-reactive electric drives with simple gearboxes that have a fixed transmission ratio. The electric traction system of the hybrid powertrain has an efficiency of over 95%. This feature reduces heat and noise emissions into the environment, and, in combination with an economical internal combustion engine (ICE) and battery, provides the vehicle with an increased travel range. In a series hybrid transmission, several internal combustion engines with generators can be used to increase power and reliability, efficient power distribution in this case is carried out by adjusting the output of the generators, which are connected in parallel to the power bus.

Switched Reluctance motors provide efficient regenerative braking and control during turns with minimal energy loss. When vehicle turns, energy is redistributed from one track to another, during braking, excess energy is supplied to the storage device (capacitor or kinetic battery).

Traction characteristics in a series hybrid system are determined by the characteristics of electric motors, so such a system does not require the use of high-torque large-sized diesel engines. Such a system does not utilize friction clutches and complex gearboxes, which significantly increases the reliability of the vehicle and decreases its weight.

A modern contactless digital control system is also used to control the transmission, and both conventional steering and joysticks can be used. If a built-in DC-AC inverter is available, the transmission generator of the parked vehicle can be used as a power station to power all kinds of auxiliary devices and various installations and buildings.