Our team of expert CAD professionals, having extensive experience with the powerful simulation tools, finite element analysis and simulation software, can take your project from a concept through engineering and CAD design, analysis, prototyping all the way to production.

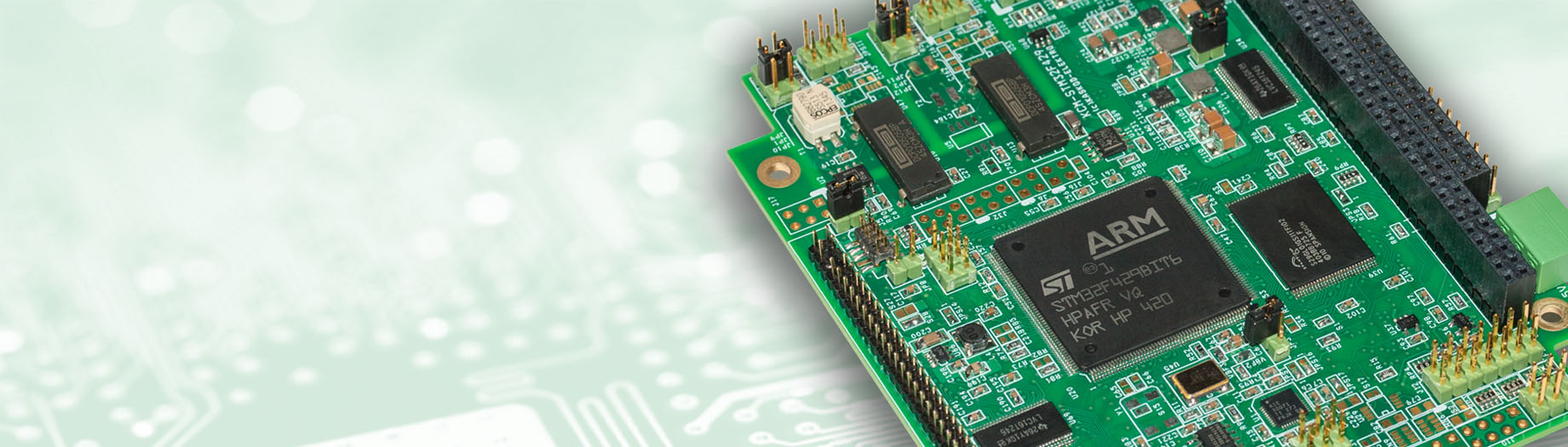

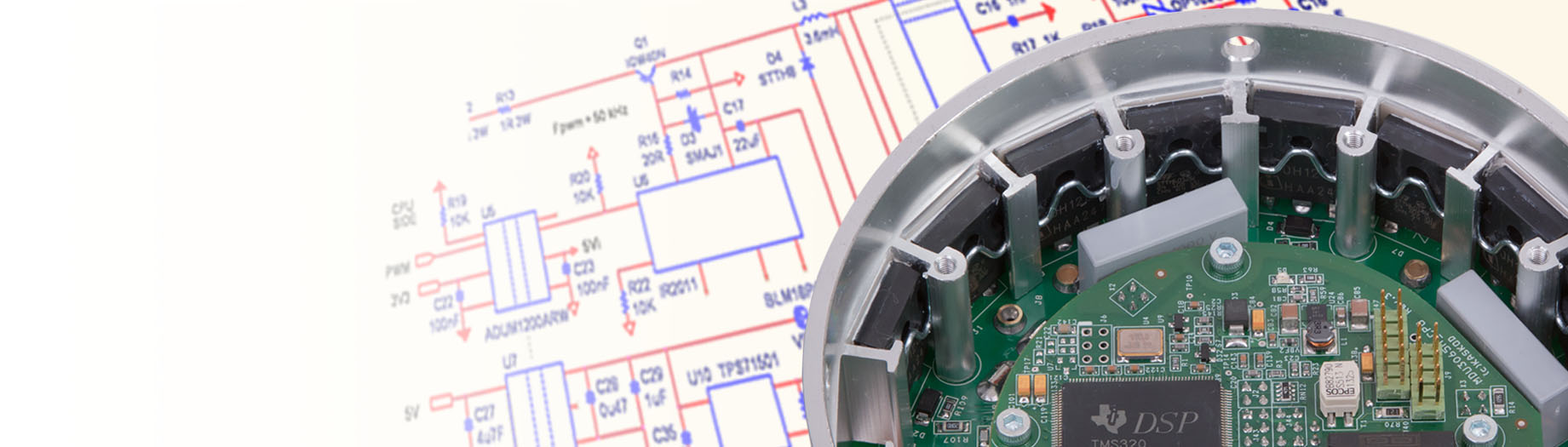

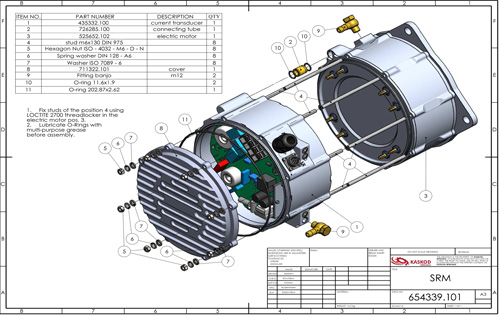

Combined 3D mechanical and electrical design:

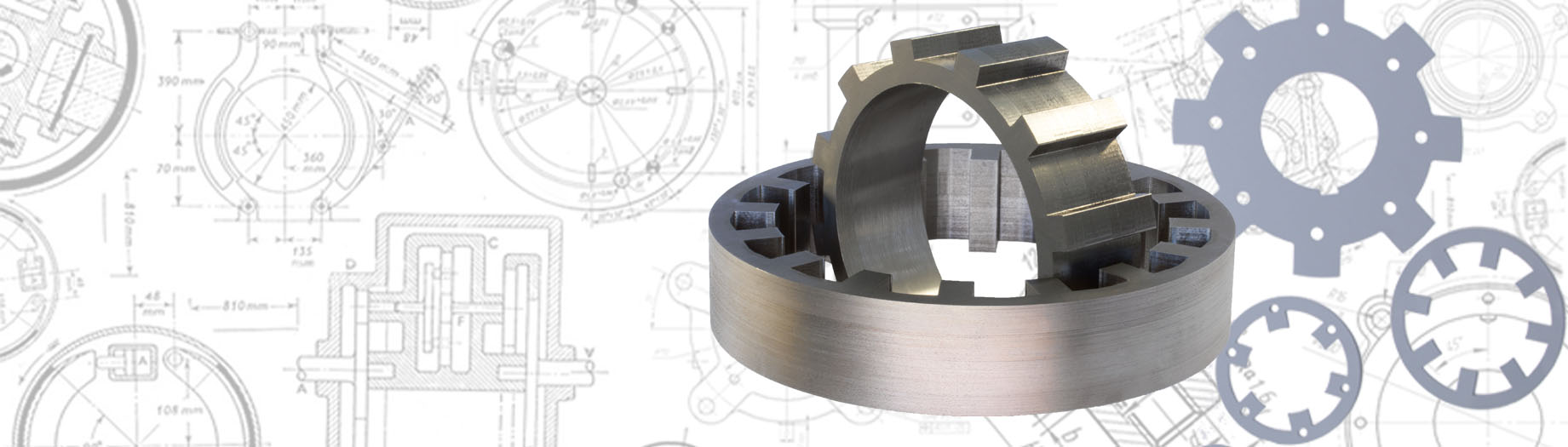

Mechanical Design: shafts, roller bearings, belts, bushings, nuts, bolts etc.

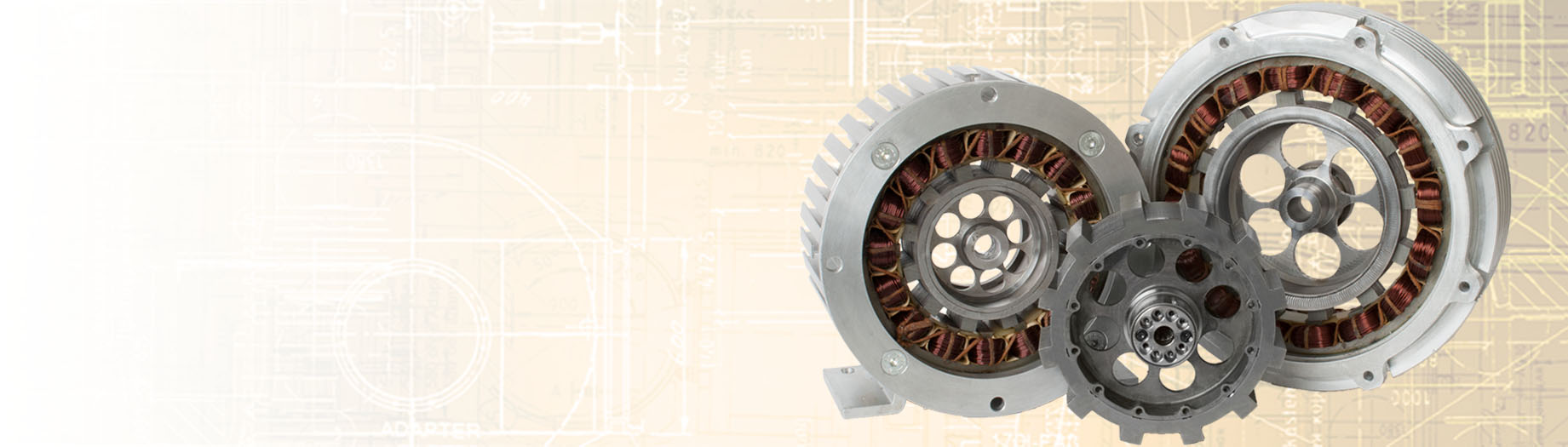

Sheet Metal Designs: rotor and stator laminations, enclosures, brackets etc.

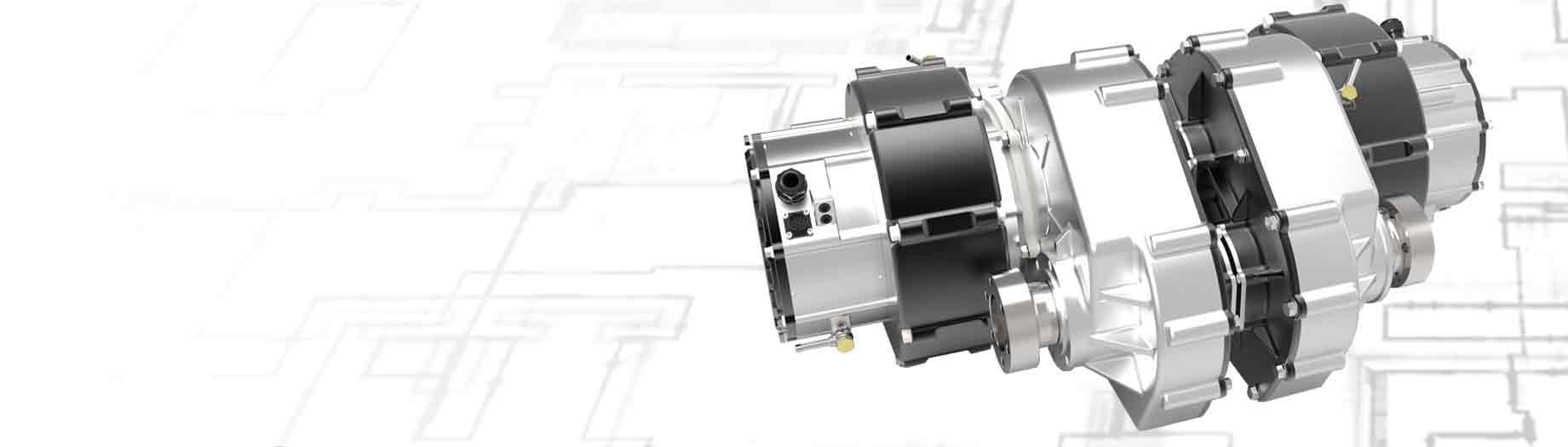

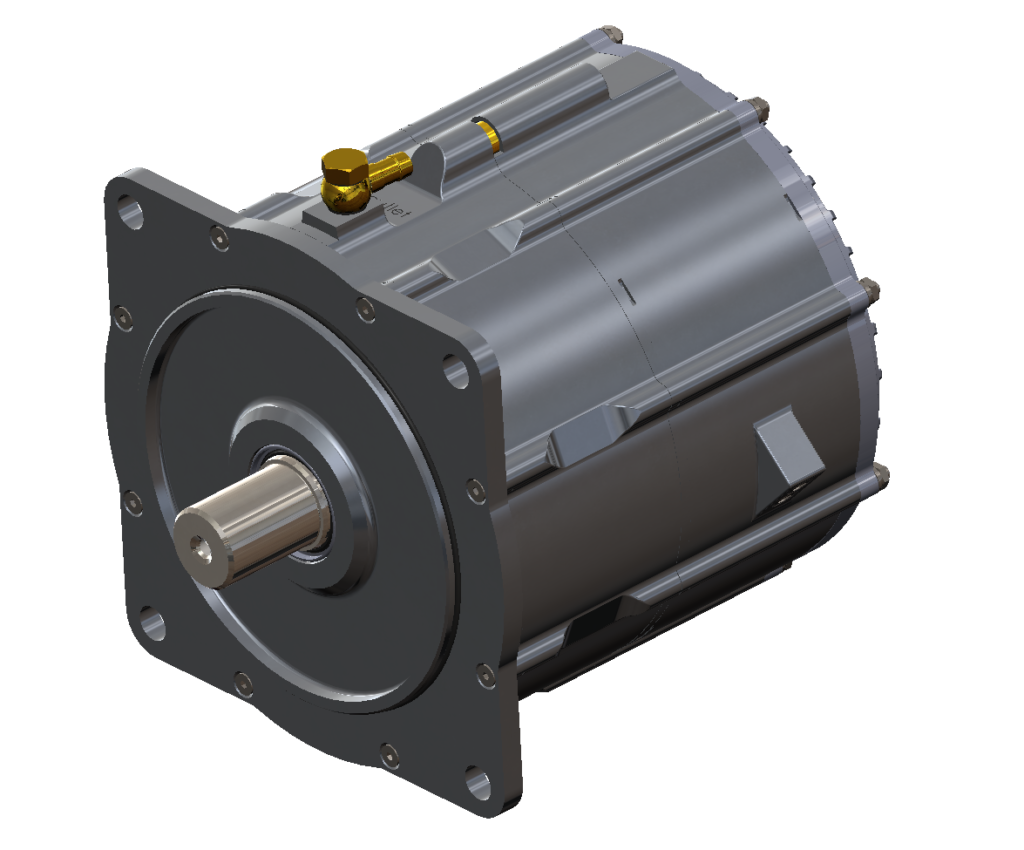

Assembly design: electric motors, gearboxes, electronic modules etc.

Manufacturing/Industrial Design Consultation.

Photorealistic 3D Renderings, 3D printing.

Rapid prototyping.

Engineering analysis:

Limits, fits and tolerances calculation.

Material selection in accordance with operation conditions.

Gear trains calculation:

- Spur gears

- Worm drives

- Hypoid gears

- Crown gears

- Racks and pinions

- Helical gears

- Bevel gears

- Multilevel planetary gears

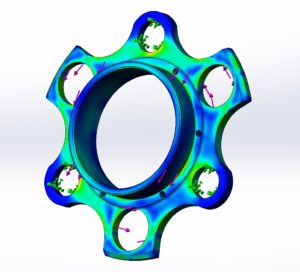

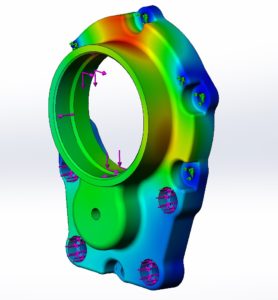

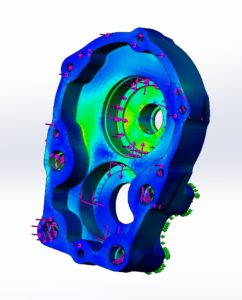

Finite Element Analysis (FEA):

- Stress Analysis

- Motion analysis

- Vibration analysis

- Thermal analysis

- Fluid flow

Manufacture of CNC-Machined Parts

TRANTRONIX offers CNC machining of custom parts which can be ordered online. CNC machining can greatly shorten your production cycle and reduce the cost of parts, and allows to quickly produce a large quantity of high-precision machined parts. Gear manufacture involves shaping, cutting, and finishing techniques to ensure the correct tooth profile, dimensional accuracy, and surface finish. Machining of castings and housings involves post-casting modifications to achieve precise dimensions, tolerances, and characteristics. We use quality materials for the parts, inspect the surface finish of the product and perform various surface treatments. Please contact us for samples, design analysis solutions, and quotations.